Ever found yourself staring at a massive warehouse, thinking, “How on earth do they move all that stuff around?” The answer, more often than not, involves the unsung heroes of heavy lifting: bridge cranes. These industrial workhorses are the backbone of countless operations, from manufacturing plants to shipping yards. But with so many options on the market, how do you even begin to choose the right one for your specific needs?

That’s where we come in! We’ve sifted through the options to bring you a comprehensive guide designed to make finding the best bridge cranes a breeze. Whether you’re upgrading your current system or outfitting a new facility, we’ll break down the key features, compare top models, and help you identify the perfect crane to keep your operations running smoothly and efficiently.

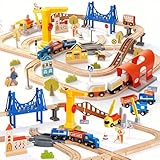

Before we jump into the best bridge cranes review, let’s take a look at these Amazon products:

Last update on 2025-12-09 / Affiliate links / #CommissionsEarned / Images from Amazon Product Advertising API

Ever Wonder How That Giant Thing Got Lifted? A Bridge Crane Introduction!

Let’s talk bridge cranes! Ever been in a massive warehouse or manufacturing plant and seen something incredibly heavy effortlessly floating across the room? Chances are, a bridge crane was the magic behind that movement. These unsung heroes of industry are essential for lifting, lowering, and transporting heavy loads with impressive precision. Think of them as the superheroes of material handling, allowing businesses to move massive items efficiently and safely.

At their core, bridge cranes are lifting mechanisms that travel along a runway system. They’re adaptable to a wide range of environments and offer superior headroom compared to other lifting solutions like jib cranes. In fact, the overhead crane market, which includes bridge cranes, is projected to reach over $5 billion by 2028, illustrating just how vital these pieces of equipment are for modern industrial operations. Their ability to precisely position heavy objects makes all the difference in productivity.

Choosing the right crane can feel daunting, but it really boils down to understanding your needs. What weight capacity do you require? What span is necessary? What kind of duty cycle will your crane face? Different crane designs excel at different tasks. Single girder cranes, for example, are typically more economical for lighter loads, while double girder cranes handle those seriously heavy-duty applications. The best bridge cranes are the ones tailored precisely to your operational requirements.

So, as we delve deeper into the world of overhead lifting, remember that selecting the best bridge cranes isn’t just about power – it’s about choosing the right tool for the job. Whether you’re operating a small machine shop or a sprawling manufacturing facility, understanding the strengths and limitations of different bridge crane models will empower you to optimize your operations and ensure safety along the way. Let’s uncover what factors make some bridge cranes stand head and shoulders above the rest!

The Best Bridge Cranes

Demag KBK Light Crane System

The Demag KBK light crane system is like the Swiss Army knife of material handling – incredibly versatile and adaptable to pretty much any workspace. Its modular design means you can customize it to perfectly fit your needs, whether you’re maneuvering delicate components or moving heavier loads around a tight corner. Plus, the smooth-running trolleys and low deadweight make for effortless operation, reducing strain on workers and increasing overall efficiency.

What really sets the KBK apart is its longevity and ease of modification. As your business grows and your needs change, this crane system can easily be reconfigured or expanded. Think of it as a future-proof investment. The system’s lightweight design also translates into lower structural support costs, which is always a welcome bonus! It’s a fantastic choice for anyone looking for a flexible and reliable lifting solution.

Konecranes CXT Wire Rope Hoist Crane

If you’re looking for a workhorse that can handle a wide range of lifting tasks, the Konecranes CXT wire rope hoist crane is a solid contender. Known for its durability and reliability, this crane is built to withstand the rigors of daily use in demanding industrial environments. The compact design maximizes headroom, allowing you to make the most of your available space, and the advanced features, like inverter control for smooth starts and stops, ensure precise load positioning.

Beyond its robust construction, the CXT offers a range of smart features that can significantly improve your operations. From load monitoring to anti-sway control, these technologies help enhance safety and productivity. While it might come with a slightly higher price tag than some competitors, the long-term benefits of its performance, safety features, and minimal maintenance requirements make it a worthwhile investment.

Stahl CraneSystems AS 7 Wire Rope Hoist

The Stahl CraneSystems AS 7 wire rope hoist is a powerhouse when it comes to heavy lifting. Built with a modular design, the AS 7 allows for easy customization to meet your specific needs. Its robust construction and high-quality components ensure reliability and longevity, even in the most challenging environments. And with features like overload protection and emergency stop, safety is paramount.

What makes the AS 7 stand out is its lifting capacity and the precision it offers. The smooth and controlled movement of the hoist allows for accurate positioning of heavy loads, minimizing the risk of damage. It also integrates seamlessly with various crane systems, offering flexibility in your material handling setup. If you need a crane that can handle serious weight with accuracy and safety, the Stahl AS 7 is definitely worth considering.

R&M Materials Handling Spacemaster SX Wire Rope Hoist

The R&M Materials Handling Spacemaster SX wire rope hoist is all about maximizing space and performance. Its low headroom design makes it ideal for facilities with limited vertical space, allowing you to lift loads higher and make better use of your existing infrastructure. The compact design doesn’t compromise on power, though, as it boasts impressive lifting capacities.

Beyond its space-saving design, the Spacemaster SX excels in delivering smooth and reliable operation. The advanced hoist technology ensures precise load control and reduces wear and tear on the equipment. Plus, the readily available spare parts and service network mean minimal downtime, keeping your operations running smoothly. If you need a powerful crane solution that doesn’t take up a lot of space, this is a great option.

Gorbel Free Standing Work Station Bridge Crane

The Gorbel Free Standing Work Station Bridge Crane offers a flexible and ergonomic solution for workstations needing overhead lifting. Because it’s free-standing, it doesn’t rely on the building’s structure for support, allowing for installation virtually anywhere. This makes it perfect for rental spaces or facilities where structural modifications are difficult or impossible. The smooth-rolling bridge and trolley make it easy to maneuver loads with minimal effort.

This crane shines in situations where flexibility and adaptability are key. It is easily relocatable, making it a cost-effective choice for companies that anticipate changes in their layout. The modular design allows for easy expansion or reconfiguration as your needs evolve. Designed with ergonomics in mind, this crane reduces strain and fatigue on workers, leading to increased productivity and a safer work environment.

Why People Need to Buy Bridge Cranes

Imagine you’re running a manufacturing plant, and your team is struggling to move heavy machinery parts across the shop floor using forklifts and manual labor. Not only is it slow and inefficient, but it’s also a safety hazard waiting to happen. That’s where a bridge crane comes in – it’s like adding a super-powered assistant that can effortlessly lift and transport those heavy loads, freeing up your team to focus on the skilled tasks they were hired for. It’s more than just lifting; it’s about streamlining your entire operation.

Consider a steel fabrication company. Moving massive steel beams with ground-based equipment can be a logistical nightmare, often leading to bottlenecks and delays. But with a bridge crane specifically designed for heavy-duty applications – maybe even the “best bridge cranes” known for their robust construction and precise control – they can seamlessly maneuver those beams into position for welding or cutting. This not only speeds up production but also reduces the risk of damage to the materials and equipment, saving money and improving the overall quality of the work.

The benefits extend beyond just the factory floor. Think about a warehouse needing to efficiently load and unload trucks. A bridge crane eliminates the need for multiple forklifts and personnel, allowing for faster turnaround times and increased throughput. And with advanced features like remote control and variable speed settings, operating the best bridge cranes becomes incredibly intuitive and safe, even for less experienced operators.

Investing in a bridge crane, particularly one from a reputable manufacturer known for its reliability and safety features, is an investment in your company’s future. It’s about increasing productivity, improving safety, and ultimately boosting your bottom line. By automating heavy lifting and material handling, you create a more efficient and profitable operation, allowing your business to thrive and stay competitive in today’s demanding market.

Understanding Different Types of Bridge Cranes

When you’re diving into the world of bridge cranes, it’s easy to get overwhelmed by the sheer variety. You’ve got single girder, double girder, underhung, top-running – the list goes on! It’s kind of like walking into a hardware store for a specific screw and being bombarded with a hundred different sizes and thread types. Knowing what each type excels at is crucial. Are you lifting bulky steel beams in a fabrication shop? Or maneuvering delicate components in a cleanroom environment? The choice significantly impacts efficiency and safety.

Let’s consider single girder bridge cranes. Think of them as the workhorses of lighter-duty applications. They’re generally more cost-effective and easier to install, making them perfect for smaller workshops or warehouses that don’t require exceptionally heavy lifting. Imagine a small machine shop where they need to move engines around. A single girder crane can do the job admirably.

Double girder bridge cranes, on the other hand, are the titans of the crane world. They’re built for handling the heaviest loads and can span greater distances. Picture a steel mill where massive slabs of steel are being moved daily. A double girder crane is essential there due to its capacity and stability. They often require more robust support structures, so that’s a factor to keep in mind.

Underhung bridge cranes offer a unique advantage by utilizing the existing roof structure. Instead of needing support columns on the ground, they hang from the ceiling. This is useful in spaces where floor space is at a premium, like a crowded warehouse. They are a good choice in older buildings as well.

Essential Safety Features and Considerations

Safety isn’t just a box to tick; it’s the foundation upon which your entire crane operation should be built. Neglecting safety features is like driving a car without brakes – you might get where you’re going, but the risk of a catastrophic accident is significantly higher. We’re talking about the well-being of your team, the integrity of your equipment, and the overall success of your operations.

Overload protection systems are key to preventing accidents caused by exceeding the crane’s capacity. These systems will automatically shut down the crane if the load is too heavy. It’s similar to the automatic shutoff on a blender when it detects too much ice. Without it, the motor would burn out, or, in a crane’s case, the crane could buckle.

Emergency stop buttons, strategically placed around the work area, are critical for quickly halting operations in case of unexpected issues. Think of it like the fire alarm in your building – you hope you never have to use it, but you’re thankful it’s there when you need it. Regular inspections and maintenance are non-negotiable aspects of crane safety. Just like your car needs oil changes and tire rotations, your crane needs regular checks to ensure all components are in good working order.

And, of course, proper training for crane operators is paramount. They need to be fully versed in safe operating procedures, hazard recognition, and emergency response protocols. It is similar to a surgeon’s training; it must be exhaustive to guarantee success. It’s not just about knowing how to push buttons; it’s about understanding the physics involved and making informed decisions in real-time.

Cost Analysis: Initial Investment vs. Long-Term Savings

Let’s talk about the dollars and cents of bridge cranes, because the upfront cost is just one piece of the puzzle. It’s easy to be swayed by the lowest initial price tag, but you need to consider the long-term implications. Just like buying a cheap car that constantly needs repairs, a poorly chosen crane can end up costing you more in the long run.

The initial investment includes not only the crane itself but also installation costs, permits, and any necessary modifications to your facility. Imagine building a new house. The price of the lumber is just the beginning; you also need to pay for the foundation, electrical wiring, plumbing, and so on. A lower-priced crane might require more extensive facility modifications, wiping out any initial savings.

However, higher-quality cranes can offer significant long-term savings through reduced downtime, lower maintenance costs, and increased efficiency. Think of it like investing in energy-efficient appliances for your home. They might cost more upfront, but you’ll save money on your energy bills every month. A reliable crane minimizes disruptions to your workflow and keeps your production line running smoothly.

Consider the cost of downtime. Every hour your crane is out of service is money lost. A crane failure might halt production, delay shipments, and even damage your reputation. Investing in a robust crane with a good track record for reliability is an investment in your business’s overall productivity and profitability. Regular maintenance and choosing the right type of crane for your application can ensure that it operates smoothly for years.

Maximizing Efficiency and Productivity with Bridge Cranes

Bridge cranes are more than just lifting machines; they’re efficiency multipliers. They can dramatically improve material handling, reduce manual labor, and optimize your workflow. Think of them as the arteries of your production process, facilitating the smooth flow of materials from one stage to the next.

Using a bridge crane, for example, to move heavy dies to injection molders, instead of using forklifts, reduces the probability of accidents. It also minimizes the time it takes to move them. A skilled operator can position the die precisely where it needs to go, saving time and reducing the risk of damage.

Optimize your layout to maximize the benefits of your bridge crane. Consider the flow of materials and the placement of workstations. It is kind of like planning a kitchen; you want everything within easy reach to minimize unnecessary steps. An efficient layout can reduce travel time and streamline your operations, leading to a significant increase in productivity.

Bridge cranes also enable you to handle materials in a safer and more controlled manner. By lifting heavy objects overhead, you reduce the risk of injury to workers. This is particularly important when handling large or awkward items. By minimizing the need for manual lifting, you create a safer and more productive work environment.

Finding the Best Bridge Cranes: Your Ultimate Buying Guide

Hey there! So, you’re in the market for a bridge crane? That’s fantastic! It’s a serious investment, no doubt, but the right bridge crane can seriously boost your productivity, improve safety, and generally make your life a whole lot easier. But with so many options out there, navigating the world of bridge cranes can feel a little overwhelming. Don’t worry, I’m here to help you cut through the noise and find the best bridge cranes for your specific needs. This guide will walk you through the crucial things to consider, so you can confidently make the right choice. Let’s get started!

1. Load Capacity: Know Your Limits (and then some!)

Alright, this one seems obvious, but it’s the most important thing. You need to accurately determine the maximum weight you’ll ever need to lift with your bridge crane. Don’t just think about what you’re lifting today. Consider future projects, potential expansions, or even temporary heavy loads. Undersizing your crane is a recipe for disaster – safety risks, equipment damage, and costly replacements. Get specific!

Think about the heaviest, bulkiest item you foresee handling regularly. Then, add a safety factor. A good rule of thumb is to add at least 25% to your maximum expected load. This provides a cushion for unexpected weight variations and extends the lifespan of your crane. Remember, it’s always better to have a crane that’s slightly over-capacity than one that’s constantly strained to its limit. Finding the best bridge cranes starts with accurately assessing your lifting capacity requirements.

2. Span and Runway Length: Measuring Up to Your Space

The span is the distance between the crane’s runway beams, and the runway length is the overall length of the area the crane will traverse. These dimensions directly impact the area your crane can cover. Before you even start looking at crane models, meticulously measure your facility’s dimensions. Consider any obstructions, such as existing machinery, support columns, or low-hanging pipes. Accurate measurements are vital for a smooth installation and efficient operation.

Imagine ordering a crane only to discover it’s a few feet too short to reach a critical workstation! Or, conversely, that it collides with existing equipment. It’s a headache you can easily avoid with proper planning. Don’t just rely on architectural drawings; physically walk the space and double-check everything. Finding the best bridge cranes also hinges on ensuring the crane perfectly fits your workspace.

3. Lift Height: Reaching New Heights (Safely)

The lift height is the maximum vertical distance the crane’s hook can travel. This is another critical dimension that needs careful consideration. Think about the tallest object you need to lift and the maximum height you need to raise it to. Will you be loading items onto trucks, stacking materials on high shelves, or positioning equipment in elevated locations? Factor in any headroom limitations imposed by your building structure or other overhead obstacles.

Insufficient lift height can severely limit your crane’s usefulness. Picture this: you have a crane with ample load capacity, but you can’t lift your equipment high enough to load it onto a truck! Frustrating, right? Don’t forget to account for the height of the lifting device itself (slings, hooks, etc.) when calculating your required lift height. The best bridge cranes offer a suitable lift height that meets all your operational requirements.

4. Duty Cycle: How Hard Will Your Crane Work?

The duty cycle refers to how frequently and intensely your crane will be used. Will it be lifting loads constantly throughout the day, or will it be used only occasionally? Understanding your duty cycle is essential for selecting a crane that’s built to withstand the demands of your operation. Heavy-duty cycles require robust components and more frequent maintenance.

Cranes are typically classified into different duty cycle ratings (e.g., light, medium, heavy, severe). A crane designed for light-duty applications won’t last long if it’s constantly subjected to heavy loads and continuous operation. Selecting the appropriate duty cycle rating is crucial for ensuring the crane’s longevity and reliability. For busy operations, finding the best bridge cranes means considering those with heavy-duty construction and components.

5. Crane Type: Choosing the Right Configuration

Bridge cranes come in various configurations, each with its own strengths and weaknesses. Common types include single-girder, double-girder, and underhung cranes. Single-girder cranes are generally more cost-effective for lighter loads and shorter spans. Double-girder cranes offer greater lifting capacity, longer spans, and better hook height. Underhung cranes are ideal for facilities with limited headroom or where the crane needs to be suspended from the building’s roof structure.

The best choice depends on your specific needs and facility constraints. Consider factors such as load capacity, span requirements, headroom limitations, and frequency of use. Consulting with a crane specialist can help you determine the most suitable type for your application. Remember, the best bridge cranes are those that perfectly match the demands of your workflow.

6. Control Systems: Getting a Handle on Things

The control system is how you operate the crane. Common options include pendant controls, radio controls, and cab controls. Pendant controls are simple and reliable, but they require the operator to be physically near the crane. Radio controls offer greater flexibility and freedom of movement, allowing the operator to control the crane from a safe distance. Cab controls are typically used for very large cranes or in environments where precise positioning is critical.

The best control system depends on your specific needs and the crane’s application. Consider factors such as operator comfort, safety, and the level of precision required. Radio controls are often preferred for their flexibility and ease of use, but pendant controls may be sufficient for simpler applications. Evaluate the ergonomics of the control system as well – a comfortable and intuitive control system can reduce operator fatigue and improve productivity. Finding the best bridge cranes often hinges on selecting a control system that complements your operational style.

7. Safety Features: Prioritizing Protection

Safety is paramount when it comes to bridge cranes. Look for cranes equipped with essential safety features such as overload protection, emergency stop buttons, limit switches, and anti-collision systems. Overload protection prevents the crane from lifting loads that exceed its rated capacity, reducing the risk of equipment damage and accidents. Emergency stop buttons provide a quick and easy way to halt the crane’s operation in case of an emergency.

Limit switches prevent the hoist from traveling too far in either direction, preventing damage to the crane and the surrounding structure. Anti-collision systems prevent collisions between multiple cranes operating on the same runway or between the crane and other objects in the workspace. Invest in safety training for your crane operators to ensure they are familiar with the crane’s safety features and proper operating procedures. Choosing the best bridge cranes always involves prioritizing safety to create a secure working environment.

FAQ

What exactly is a bridge crane, and how does it differ from other types of cranes?

Bridge cranes are a type of overhead crane that operates on a fixed track system, typically along the walls of a building or within a structural framework. Imagine a bridge spanning the width of your workspace, with a hoist mechanism moving along that bridge. That’s essentially how a bridge crane works! They’re incredibly versatile for lifting and moving heavy objects within a defined area.

Unlike other types of cranes like jib cranes (which rotate around a fixed point) or gantry cranes (which have their own legs and can be moved to different locations), bridge cranes are optimized for covering a larger rectangular area. They’re ideal when you need to consistently lift and move materials within a dedicated workspace, providing a much wider range of motion compared to other lifting solutions. Think of it this way: if you need to move something from one end of a warehouse to the other, a bridge crane is your go-to option!

What factors should I consider when determining the right lifting capacity for my bridge crane?

Choosing the right lifting capacity is super important for safety and efficiency! First, analyze the weight of the heaviest loads you’ll regularly be lifting. Don’t just consider the absolute heaviest object you might lift once a year; focus on the typical weight of your day-to-day operations. It’s always better to overestimate slightly than to underestimate and risk overloading the crane.

Besides the weight of the load itself, consider the weight of any lifting attachments you’ll be using, such as slings, grabs, or magnets. These can add significant weight to the total load. Then, add a safety factor! Most experts recommend adding at least 25% to your calculated maximum load to account for unexpected weight variations or uneven load distribution. This gives you a comfortable buffer and ensures the crane operates safely within its limits.

What are the main types of bridge cranes available, and which one is best suited for my needs?

There are several types of bridge cranes, but the most common are single girder and double girder cranes. A single girder crane uses one bridge beam, making it lighter and generally more cost-effective for lighter lifting capacities. They’re great for warehouses or smaller manufacturing facilities where space might be a bit more limited.

Double girder cranes, on the other hand, use two bridge beams, offering much higher lifting capacities and greater stability, especially for wider spans. They’re often preferred in heavy industrial environments like steel mills or shipyards. To decide which is right for you, consider the weight of your typical loads, the span you need to cover, and your budget. If you’re unsure, it’s always a good idea to consult with a crane specialist!

What are the key safety features I should look for in a bridge crane?

Safety is paramount when it comes to bridge cranes! You want to ensure the crane you choose is equipped with features that protect your workers and your equipment. Look for overload protection systems, which automatically prevent the crane from lifting loads exceeding its capacity. Emergency stop buttons are also essential; they should be easily accessible to quickly halt all crane movements in case of an emergency.

Also, make sure the crane has features like limit switches to prevent over-travel of the hoist and trolley. This prevents the crane from running into the end stops of the runway. Consider cranes with anti-collision systems, especially if you have multiple cranes operating in the same area. Regular inspections and maintenance are crucial, too, so look for a crane that’s easy to inspect and maintain. Don’t hesitate to ask the manufacturer about the specific safety features included and their certifications!

How much maintenance is typically required for a bridge crane, and what are the associated costs?

Regular maintenance is key to keeping your bridge crane running smoothly and safely. Think of it like taking your car in for routine checkups – it prevents bigger problems down the road. The amount of maintenance required depends on the crane’s usage frequency and the operating environment, but generally includes things like lubricating moving parts, inspecting cables and hooks, and checking electrical connections.

The costs associated with maintenance can vary widely. Some tasks can be handled in-house with trained personnel, while others require specialized technicians. It’s a good idea to factor in the cost of these services when budgeting for your crane. Consider asking the manufacturer for a recommended maintenance schedule and estimated costs. Proactive maintenance can save you significant money in the long run by preventing costly breakdowns and extending the lifespan of your crane!

How difficult is it to install a bridge crane, and can I do it myself?

Installing a bridge crane is not a DIY project for the average person! It’s a complex process that requires specialized knowledge, equipment, and adherence to strict safety regulations. Attempting to install it yourself could lead to serious injury or damage to the crane and your facility.

It’s always best to hire a qualified and certified crane installation company. They have the expertise to properly assess your building structure, ensure the crane is installed correctly, and perform necessary load testing to verify its safe operation. They’ll also be familiar with local regulations and permitting requirements. While it might seem like a way to save money upfront, professional installation is a crucial investment in the long-term safety and reliability of your crane.

What is the typical lifespan of a bridge crane, and how can I extend it?

A well-maintained bridge crane can last for many years – even decades! Typically, you can expect a lifespan of 20-30 years or more with proper care. However, the actual lifespan depends on factors like usage frequency, the severity of the operating environment, and how diligently you follow the manufacturer’s recommended maintenance schedule.

To extend the life of your crane, prioritize regular inspections and maintenance. Address any minor issues promptly before they escalate into major problems. Ensure operators are properly trained and understand the importance of operating the crane within its rated capacity. Keep the crane clean and free from debris, and protect it from harsh environmental conditions if possible. By investing in proper care and maintenance, you can maximize the lifespan of your bridge crane and ensure a reliable and safe lifting solution for years to come.

Conclusion

Choosing the right bridge crane for your operation might seem like a huge task, but armed with this knowledge, you’re well-equipped to find the perfect fit. Think of it this way: the best bridge cranes aren’t just pieces of equipment; they’re investments in efficiency, safety, and ultimately, your company’s future success. Picture the increased productivity, the smoother workflow, and the enhanced safety your team will experience with the right lifting solution.

Now, it’s time to take that first step! Don’t be afraid to delve a little deeper into your specific needs, revisit your priorities, and confidently select the crane that’s going to transform your operations. This isn’t just about buying a crane; it’s about building a more productive, safer, and ultimately, more successful future. You’ve got this!